MEYVE SUYU VE ŞARAP UYGULAMALARI

MEYVE SUYU

Meyve suyu %80-90 su ve çözünebilir katılar ve çözünemeyen katılardan oluşur. Çözünebilir katılar; şeker, organik asitler, vitaminler, polifenoller, aroma bileşikleri, pigmentler, tuzlar gibi molekül ağırlığı 1 kDa’dan küçük olan moleküller ve polisakkaritler, proteinler ve tanninler gibi molekül ağırlığı 1 kDa’dan büyük olan makromoleküllerdir. Çözünemeyen katılar ise hücre, hücre duvarları, fiberler, kristaller, nişasta granülleri ve mikroorganizmalardır. Membran sistemleri seçiminde içerik çok önem taşımaktadır.

Meyveler uniform şekilde parçalanıp ezildikten sonra preslenerek meyve püresi haline getirilir. Geleneksel yöntem, kiselgur filtresi ve uzun süreler tanklarda bekletme işlemlerini ayrıca çok miktarda enzim, jelatin ve kimyasal vs kullanımı gerektirir. Arındırma/bulanıklık giderme işleminden sonra taşıma ve depolamayı kolaylaştırmak için konsantrasyon işlemi yapılır. Geleneksel yöntemde evaporasyonla birlikte aroma kazanma birimi ile konsantre edilerek kuru madde değeri 11-12 brix iken 70 brixe çıkarılır. İsteğe bağlı olarak nakliye öncesi pastörize edilir.

Bu proseste UF, MF ve RO membran sistemlerinin kullanım aşamaları verilmiştir. MF ile istenmeyen süspanse katılar, bakteriler vs uzaklaştırdıktan sonra UF ile konsantrasyon işlemi yapılır. Ultrafiltrasyon (UF) konsantrasyon işlemi için ekonomik ve kalite açısından çok etkili bir alternatiftir. Bu yöntemle berraklık ve eski tekniklerle elde edilemeyen çok iyi bir kalite sağlanır. Yüksek verim, yüksek kapasite ve çok iyi kalite sağlanabilmesi için enzim uygulaması ve ön filtreleme işlemleri UF öncesi yapılmalıdır. Endüstride kullanılan polimerik ve seramik tübüler membran sistemleri membran değiştirme maliyeti yüksektir ve kesikli sistem çalışır. Bu nedenle sistemde sorun yaşanır. Son gelişmelerle bu sorunların üstesinden gelebilecek spiral sarımlı membranlar geliştirilmiştir.

MİKROFİLTRASYON-ULTRAFİLTRASYON

- Çözünemeyen katıların uzaklaştırılması,

- Mikroorganizmaların uzaklaştırılması,

- Meyve suyu bulanıklık giderme,

- Konsantre edilmesi

TERS OZMOS

- Suyun uzaklaştırılarak konsantre edilmesi

ŞARAP

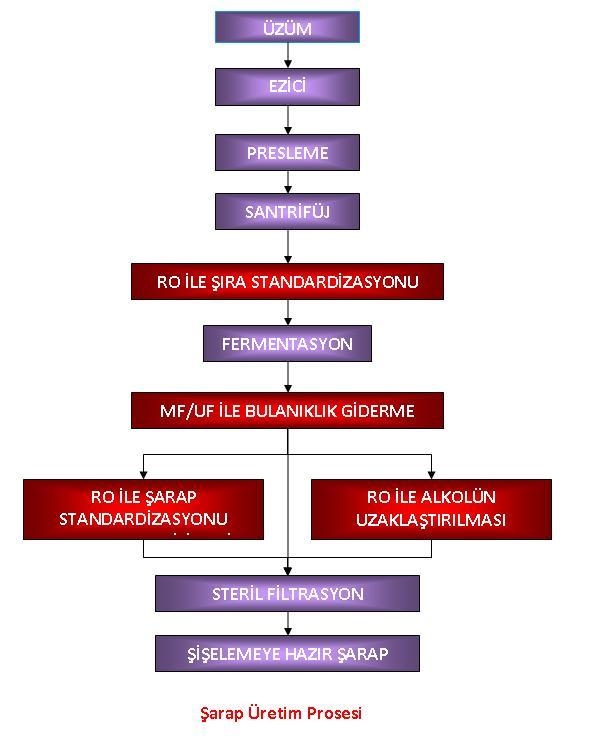

Geleneksel şarap yapımı, üzümlerin ezilmesi ve preslenmesini şıranın standardize edimesi takip eder. Preslenmiş üzüm suyu santrifüjlenir ve fermentasyon tankına aktarılarak maya ilave edilir. Fermentasyon tamamlandıktan sonra maya şaraptan uzaklaştırılır ve şarap eskitmek için fıçılara aktarılır. Olgun şarapta bulanıklık giderilir, tortular stabilize edilir, steril filtre edilir ve şişelenir. Membran prosesleri üretim prosesindeki farklı ayırma proseslerinin yerini alabilir. Şarabın tadı kötüleşirse ya da alkolsüz şarap istenirse bu aşamalar steril filtrasyon sonrası yapılır.

Fermentasyon sonrası şarabın saflaştırılması istenen kaliteyi sağlamak için santrifügasyon ve kiselgur filtrasyon gibi aşamaları içerir. MF/UF kullanılarak bulanıklık giderme, stabilizasyon ve steril filtrasyon işlemleri sürekli proseste birleştirilerek aşamaların sayısı azaltılır. Şarabın saflaştırılmasında başarılı olabilmek için membranın kirlenme davranışı ve por büyüklüğüne göre membran seçimi önemlidir.

Fermentasyon sonrası şarabın saflaştırılması istenen kaliteyi sağlamak için santrifügasyon ve kiselgur filtrasyon gibi aşamaları içerir. MF/UF kullanılarak bulanıklık giderme, stabilizasyon ve steril filtrasyon işlemleri sürekli proseste birleştirilerek aşamaların sayısı azaltılır. Şarabın saflaştırılmasında başarılı olabilmek için membranın kirlenme davranışı ve por büyüklüğüne göre membran seçimi önemlidir.

Kritik şarap bileşenlerinin seçimi ve boyutları tabloda verilmiştir.

MİKROFİLTRASYON / ULTRAFİLTRASYON

- Bulanıklık giderme, stabilizasyon ve mikroorganizma uzaklaştırma işlemleri

- Genel olarak kullanılan MF membranları por çapı beyaz şarap filtrasyonu için 0.20 ve 0.45 mm arası kırmızı şarap filtrasyonu için ise 0.45 ve 0.65 mm’dir.

TERS OZMOS

- Suyun uzaklaştırılması, şekerin konsantre edilmesi ile şıra stabilizasyonu

- Eski şarabın gençleştirilmesi

- Alkolsüz şarap üretimi