MİKROFİLTRASYON MEMBRANLARI

Mikrofiltrasyon, akışkandaki partiküllerin basınç yardımıyla mikrogözenekli membrandan geçerek uzaklaştırıldığı bir prosestir. Mikrofiltrasyon prensip olarak, ters osmoz, ultrafiltrasyon ve nanofiltrasyonla temelde aynı işlemlerdir sadece ayrıştırılan materyalin boyut aralığı farklıdır.

Mikrofiltrasyon, akışkandaki partiküllerin basınç yardımıyla mikrogözenekli membrandan geçerek uzaklaştırıldığı bir prosestir. Mikrofiltrasyon prensip olarak, ters osmoz, ultrafiltrasyon ve nanofiltrasyonla temelde aynı işlemlerdir sadece ayrıştırılan materyalin boyut aralığı farklıdır.

Mikrofiltrasyonun özellikleri ve Mekanizması

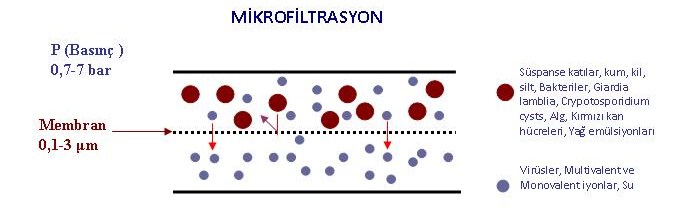

Mikrofiltrasyon membranının gözenek boyutu aralığı 0.1-3 µm arasındadır. Moleküler ayırma sınırı > 1000,000 Da olan makromolekülleri ve askıda katı maddeleri ayıran bir sistemdir. MF ile uzaklaştırılan maddeler; nişasta, bakteri, yağ, küf, maya, emülsifiye yağlar, kum, silt, kil, Giardia lamblia, Crypotosporidium cysts, alg, bazı bakteri suşlarıdır. Virüslere karşı kesin bir bariyer değildir. Genellikle işlem basıncı oldukça düşük olup 0,7 Bar ile 7 Bar arasındadır.

Mikrofiltrasyon membranlarının üretiminde kullanılan materyaller selüloz nitrat veya asetat, poliviniliden florit (PVDF), poliamitler, polisülfon, polikarbonat, polipropilen vs. gibi naturel ve sentetik polimerlerdir.

Mikrofiltrasyon membranları seçilirken membranın mekanik gücü, sıcaklığa dayanıklılık, membranın kimyasal uyumluluğu, hidrofobilite, hidrofilite ve geçirgenlik gibi özellikleri dikkate alınmalıdır.

AMFOR MF SPİRAL SARILI MEMBRANLAR

AMFOR Spiral mikrofiltrasyon membranlar, çeşitli uygulamalarda mükemmel bir performans sunar. Nispeten yüksek akışlı besleme suyu membran yüzeyi boyunca 10-50psi basınç altında pompalanır. Az miktarda su (%5-10) membrandan geçer. Su dengesi sonraki membran elemanına gider ya da geri döner. Buna ek olarak, az bir miktar konsantre sıvı sistemden uzaklaştırılır. Bu çapraz akış süreci mikrofiltrasyon membran yüzeyinde kirlenmeyi en aza indirmeye yardımcı olur.

- Malzeme: PES ve PVDF

- Çeşitli MWCO membranlar:0.1um, 0.2um, 0.3um

- Çeşitli çap (3,8-10,3 inç)

- Çeşitli uzunluklarda (33-56 inç)

- Çeşitli besleme aralayıcılar (24-80 milyon)

- Yüksek pH / yüksek sıcaklık için özel tasarım

Avantajları

- Maksimum dayanıklılık ve uzun ömür için tasarlanmıştır.

- 3-A, FDA ve USDA standartlarına uygundur.

- Geniş bir uygulama yelpazesi için standart çap veya özelleştirilmiş yapılandırmaları mevcuttur.

- Kirlenmeye karşı yüksek dirence sahiptir.

AMFOR MF MEMBRANLARI

![]() MF-PES Serileri (Gıda, Süt sanayi, İlaç ve Biyolojik uygulamalar)

MF-PES Serileri (Gıda, Süt sanayi, İlaç ve Biyolojik uygulamalar)

![]() MF-PVDF Serileri (Elektrokaplamalı Boya, Tekstil ve Arıtma işlemleri)

MF-PVDF Serileri (Elektrokaplamalı Boya, Tekstil ve Arıtma işlemleri)