ULTRAFİLTRASYON MEMBRANLARI

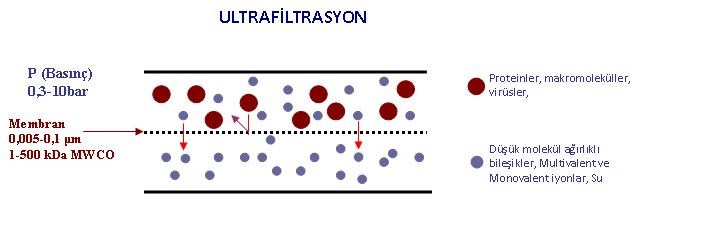

Ultrafiltrasyon, sıvıların hidrostatik basınç ile yarı geçirgen membrana karşı itildiği bir çeşit membran filtrasyonudur. Ultrafiltrasyon (UF) temel olarak, basınçla çalışan eleme prensibi ile yönetilen ve partikül boyutuna bağlı ayırma prosesidir. Düşük basınç altında büyüklüklerine göre seçilmiş maddeler ayrılır.

Ultrafiltrasyon, sıvıların hidrostatik basınç ile yarı geçirgen membrana karşı itildiği bir çeşit membran filtrasyonudur. Ultrafiltrasyon (UF) temel olarak, basınçla çalışan eleme prensibi ile yönetilen ve partikül boyutuna bağlı ayırma prosesidir. Düşük basınç altında büyüklüklerine göre seçilmiş maddeler ayrılır.

Ultrafiltrasyon prosesinde, istenen makromolekülün sürekli bir sistemde saflaştırılması, konsantrasyonu ve fraksiyonlanması işlemleri yapılabilir.

MEMBRAN ÖZELLİKLERİ

Ultrafiltrasyon membranları, molekül ağırlığı ayırma sınırı (Molecular weight cut-off-MWCO) ile tanımlanır. Birçok durumda ayırma etkinliği sadece ayırma sınırına bağlı değildir. Aynı zamanda membran ve ham çözeltinin karşılıklı ilişkisinden de etkilenir. Ultrafiltrasyon için işlem basıncı genellikle 3 ve10 Bar arasındadır.

Ultrafiltrasyon membranları 0,005-0,1 μm arasında gözenek çapına sahiptir ve böylece molekül ağırlığı ayırma sınırı MWCO 1.000 -500 000 Da olan makromolekül içeren sıvılar saflaştırılır, fraksiyonlanır ya da konsantre edilir.

Seçilen MWCO ya göre membran, çözünmüş tuzların, su ve suda çözünmüş düşük molekül ağırlıklı maddelerin geçmesinei izin verir. Süspanse katılar ve yüksek molekül ağırlıklı suda çözünmüş maddeler membranda alıkonarak konsantre edilecektir.

Genel olarak proses biyomoleküllerin, bakterilerin, virüslerin, polimerlerin, kolloidal partiküllerin ve şeker moleküllerinin alıkonması için uygundur.

AMFOR UF MEMBRANLARI

AMFOR geniş bir uygulama yelpazesine sahip olan Ultrafiltrasyon membranlarının dünyanın en büyük ve profesyonel tedarikçilerinden biridir.

Özellikler

• Çeşitli çap (3,8-10,3 inç)

• Çeşitli uzunluk (33-56 inç)

• Çeşitli örnek taşıyıcılar (24-80 mil)

• Yüksek pH / yüksek sıcaklık için özel tasarım

• Çeşitli MWCO membranlar (1000 – 500.000)

Avantajlar

- Membran gözenek boyutunun üzerindeki partiküller, pirojenler, mikroorganizmalar ve kolloidlerin etkin şekilde uzaklaştırılmasını sağlar.

- Daha düşük enerji kullanarak çok yüksek kalitede su üretilir.

- Kurulumu kolaydır.

- Bakımı ucuz ve kolaydır.

AMFOR UF HİJYEN MEMBRANLAR

![]() PES serileri (Gıda, Süt sanayi, İlaç ve biyolojik uygulamalar)

PES serileri (Gıda, Süt sanayi, İlaç ve biyolojik uygulamalar)

![]() PAN serileri (Yağ beslemesuyu, E-kaplama prosesi, atık su arıtımı)

PAN serileri (Yağ beslemesuyu, E-kaplama prosesi, atık su arıtımı)

![]() PVDF serileri (EDUF membranlar- Anodik- katodik elektrokaplamalı boya, Atık su geri dönüşümü, Alkali temizleyici geri kazanımı, PVA geri kazanımı)

PVDF serileri (EDUF membranlar- Anodik- katodik elektrokaplamalı boya, Atık su geri dönüşümü, Alkali temizleyici geri kazanımı, PVA geri kazanımı)

![]() PS serileri (Gıda, Süt sanayi, İlaç ve biyolojik uygulamalar)

PS serileri (Gıda, Süt sanayi, İlaç ve biyolojik uygulamalar)

AMFOR UF EDUF MEMBRANLAR

EDUF spiral membranlar anodik ve katodik elektrokaplamalı boya ile birlikte kullanılmak üzere üretilmiştir.

![]() 2.5″& 4.0″ SPIRAL EDUF MEMBRAN SPESİFİKASYON

2.5″& 4.0″ SPIRAL EDUF MEMBRAN SPESİFİKASYON

![]() 6″ SPIRAL EDUF MEMBRAN SPESİFİKASYON

6″ SPIRAL EDUF MEMBRAN SPESİFİKASYON

![]() 8″ SPIRAL EDUF MEMBRAN SPESİFİKASYON

8″ SPIRAL EDUF MEMBRAN SPESİFİKASYON

![]() 8″ SPIRAL EDUF-8040-HP SPESİFİKASYON

8″ SPIRAL EDUF-8040-HP SPESİFİKASYON

AMFOR UF TÜBÜLER MEMBRANLAR

AMFOR’un 10 foot multi-tubular UF7 membranları anodik-katodik boyalarla kullanım için dizayn edilmiştir. Daha fazla bilgi için….