SÜT ÜRÜNLERİ UYGULAMALARI

Süt sanayisinde membranlar; süt ürünlerinin saflaştırılması, fraksiyonlanması ve konsantrasyonu işlemleri için kullanılır. Peynir Altı Suyu (PAS) işlemlerine membran teknolojisinin uygulanmasıyla saf proteinlerin üretilmesi ve ticari kullanımı sayesinde peynir üretimindeki yan ürün atığının değerli bir ürüne dönüştürülmesi sağlanır.

Peynir ve fermente ürünlerin üretim teknolojisinde yaygın olarak evaporasyon tekniği ve enzim kullanılır. Bu teknikler sütün yapısında değişikliklere neden olur. Membran teknolojisi kullanılarak süte ısıl işlem uygulanmadığı ve herhangi bir biyokimyasal reaksiyon gerçekleşmeyeceği için sütün yapısı bozulmaz ve özel süt bileşenleri elde edilir. Filtre edilmiş süt direkt olarak peynir, dondurma ve yoğurt üretiminde kullanılabilir.

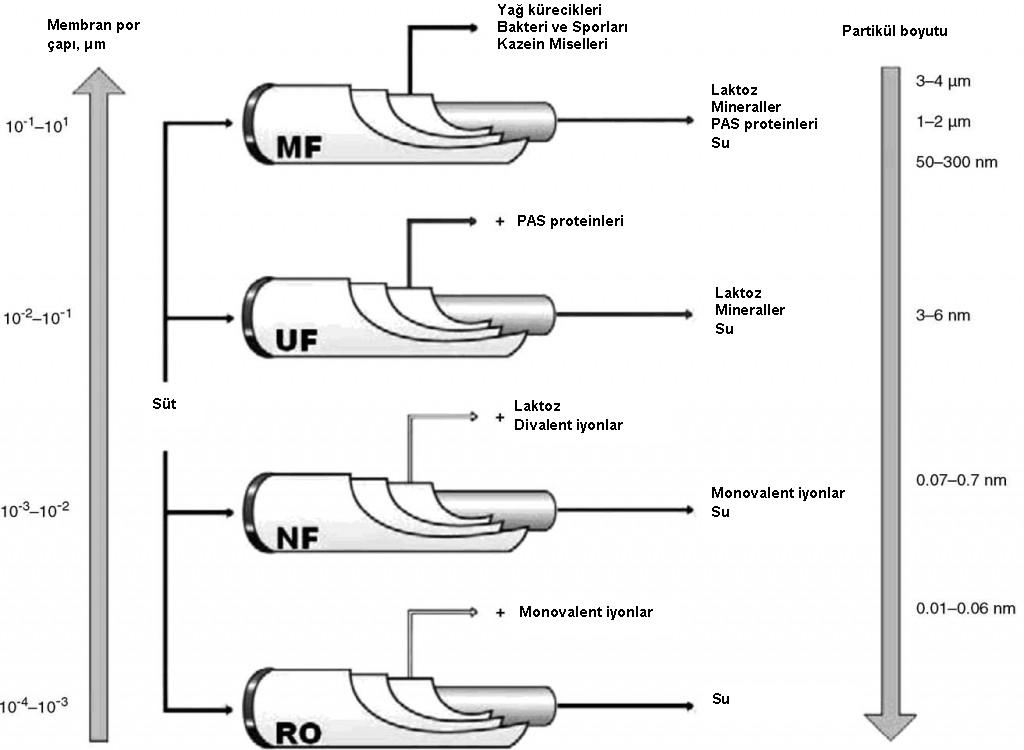

Süt, farklı por çapında ve molekül ayırma sınırında (MWCO) membranlar kullanılarak ayırma, saflaştırma ve ya sütteki seçilen bileşenlerden diğer bileşenlerin fraksiyonlanması ile modifiye edilebilir.

Basınç ile çalışan membran prosesleri olan MF, UF, NF ve RO süt sanayisinde en yaygın kullanılan membran porseslerdir.

Membran teknolojilerinin avantajları;

- Az enerji tüketimi

- Süte ısıl işlem uygulanmaması

- İşletme için taze suyun geri kazanımı

- Atık arıtım maliyetinin azaltılması

- Daha az yer ve sermayeye gereksinim olması

Cross-Flow Membrane Applications in the Food Industry, Frank Lipnizki

Şekil 1 Süt sanayide membran teknolojisi uygulamaları

- Peynir sütünden, süt tozu yapılacak sütten ve içme sütünden küçük partikül, bakteri ve sporların uzaklaştırılması (MF),

- Yoğurt üretimi için kuru madde artırımı (UF)

- Uzun ömürlü süt üretimi (MF),

- Süt proteinlerinin fraksiyonlanması (MF),

- Süt yağ içeriğinin standardizasyonu (MF),

- Yüksek proteinli peynir altı suyu konsantresi (WPC) için peynir altı suyundan yağın uzaklaştırılması (MF)

- Salamura suyunun arıtılması için bakteri, maya ve küflerin uzaklaştırılması (MF)

- Süt konsantrasyonu (RO)

- Süt tozu üretimi (MP)

- Süt protein konsantresi (MPC)

- Süt proteini fraksiyonlanması

- UF sonrası konsantrasyon (RO)

- Laktoz içermeyen süt ürünleri (UF)

PEYNİR İÇİN UYGULAMALAR

- Peynir yapımı öncesi süt konsantrasyonu (UF)

- Peynir altı suyundan ve yağsız sütten kazein misellerinin, yağ globülleri ve somatik hücreler ve ya bakterilerin uzaklaştırılması (UF),

- Peynir altı suyu ve Süt proteini konsantresi (UF)

- Peynir altı suyu ve Süt proteini izolatı(UF)

- Salamura arıtma (UF)

PEYNİR ALTI SUYU İÇİN UYGULAMALAR

- Peynir altı suyu tozu üretimi

- Peynir altı suyu konsantresi üretimi (WPC) üretimi

- Peynir altı suyu izolatı (WPI) üretimi

- Süt sanayisinde peynir altı suyu arıtımı(UF)

- Peynir altı suyu demineralizasyonu (NF)

- Peynir altı suyu konsantrasyonu (NF)

- Peynir altı suyu veya UF süzüntüsünden kısmen tuzların uzaklaştırılması(NF)

- Peynir altı suyu konsantrasyonu (RO)

- Peynir altı suyundan küçük partikül, bakteri ve sporların uzaklaştırılması (MF),

DONDURMA UYGULAMALARI

- Dondurma endüstrisinde laktoz içeriğin azaltılması ve protein içeriğinin artırılması

- Karbohidratı azaltılmış süt ve dondurma üretimi (UF),

- Dondurma karışımı için yağsız sütün kuru madde artırımı (RO)